DURING the Napoleonic Wars, Admiral Nelson engaged 38 Spanish and French ships off the coast of Spain near Cape Trafalgar.

It was October 1805 and Nelson had a battle plan which involved splitting the enemy line into three and engaging the middle third which included their flagship in close combat. This was a break with traditional naval tactics at the time and Nelson needed to be confident about the manoeuvrability of his ships and their firepower.

History tells us that Nelson’s battle plan succeeded.

At the end of the battle the British had destroyed 19 enemy ships and killed or wounded 6,000 French and Spanish men, with 20,000 men captured. Nelson’s victory ended Napoleon’s plans to invade Britain. He became a national hero but little was said that his success at Trafalgar was in part due to the skill and expertise of a Southampton father and son, both called Walter Taylor.

In 1734 Walter Taylor, a very skilled and innovative ship’s carpenter, and his wife Elizabeth had a son they named Walter.

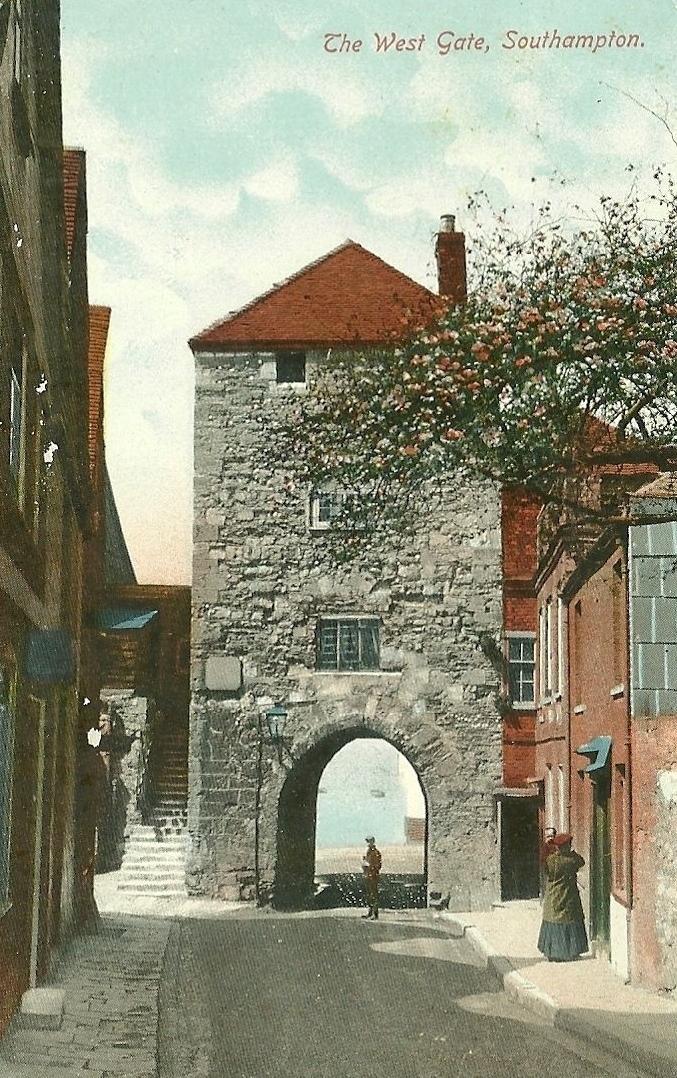

Young Walter was indentured as an apprentice to Mr Messer, a ship’s pulley block maker, in Westgate Street, Southampton, when he was 14 years old.

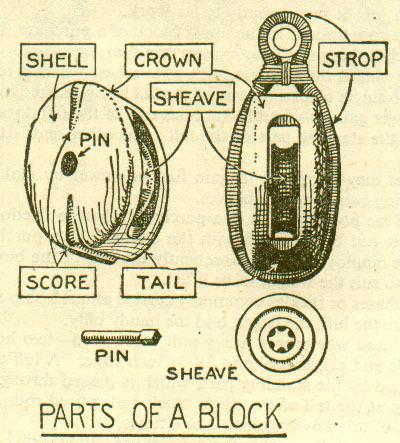

His father, having left the navy, spent time researching the manufacturer of ship pulley blocks as, from his experience, they were not very reliable – the main reason being that they were individually handmade. This led to variations in quality which could affect performance at sea. Ships relied on pulley blocks to control the sails and to position cannons for firing from the gun ports, and handmade blocks were prone to snagging and jamming.

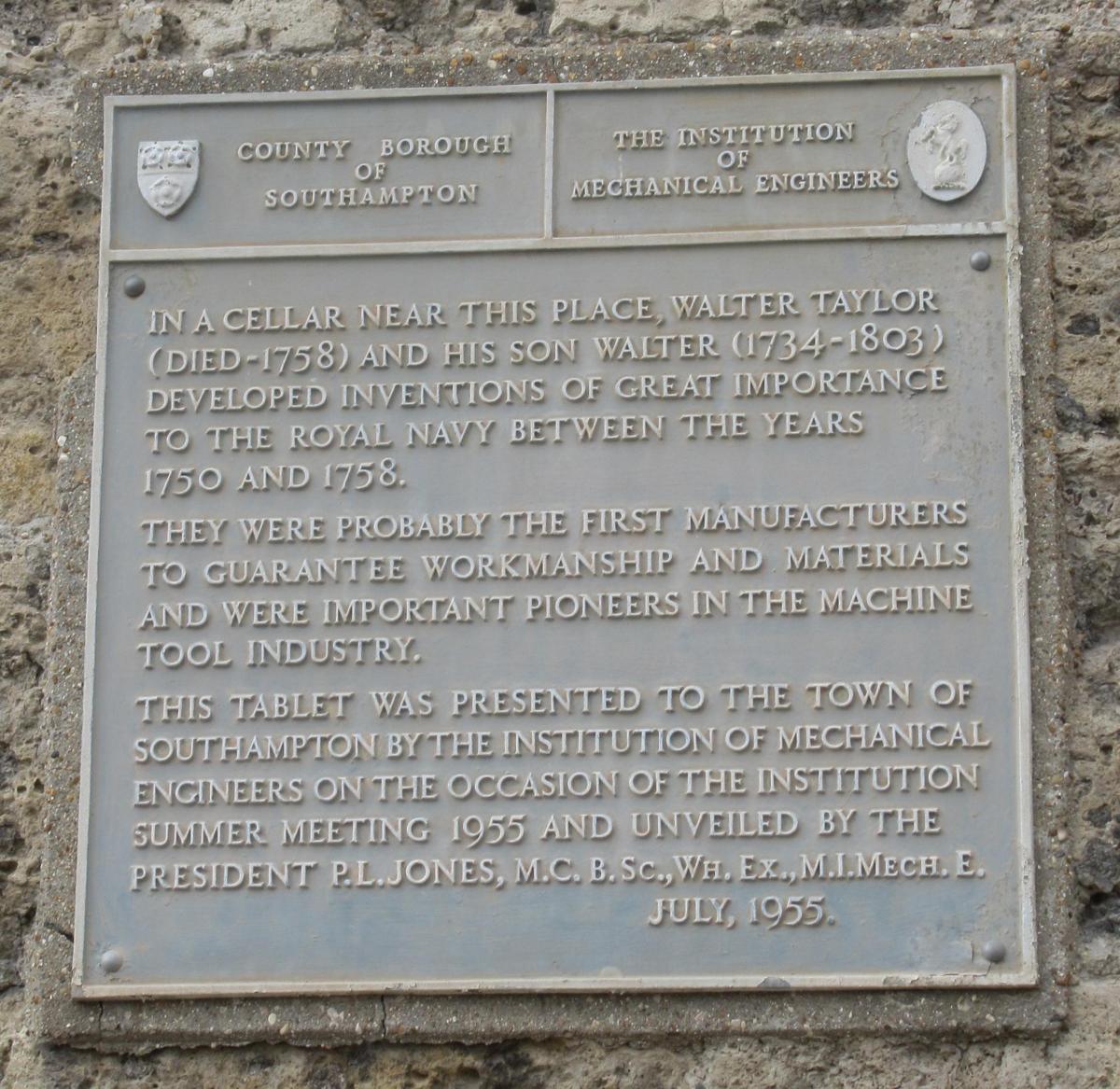

When Messer died in 1754, the Taylors bought his block-making business and developed sawing, boring and turning machinery to mass-produce the blocks to greater accuracy and quality. With the help of the local MP and a member of the admiralty, the Taylors’ blocks were tested by the navy and proved to be so successful that the navy bought all the stock.

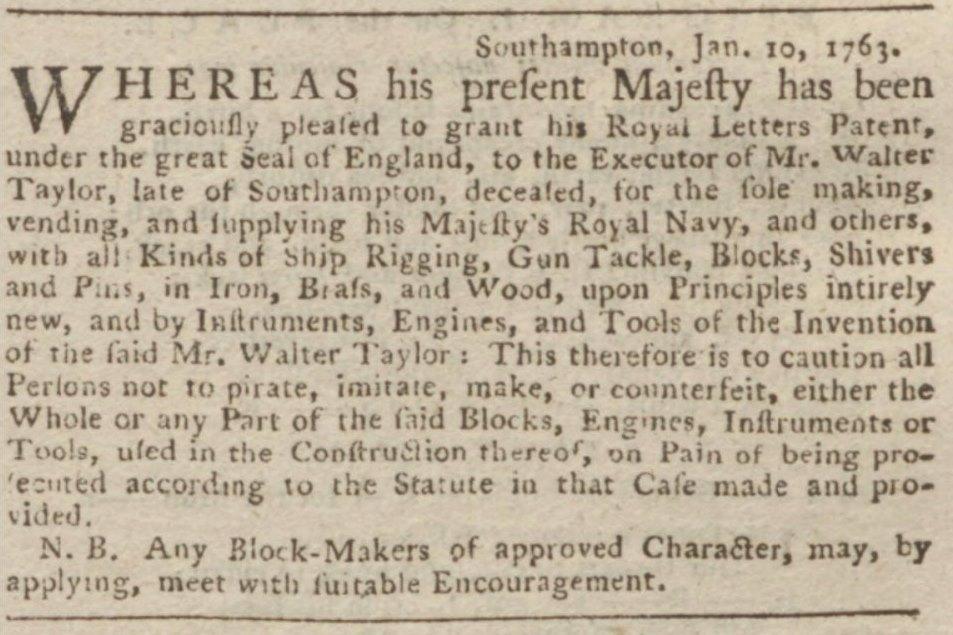

The father died in 1762 and young Walter continued the business which produced blocks for the admiralty from 1759 until 1801.

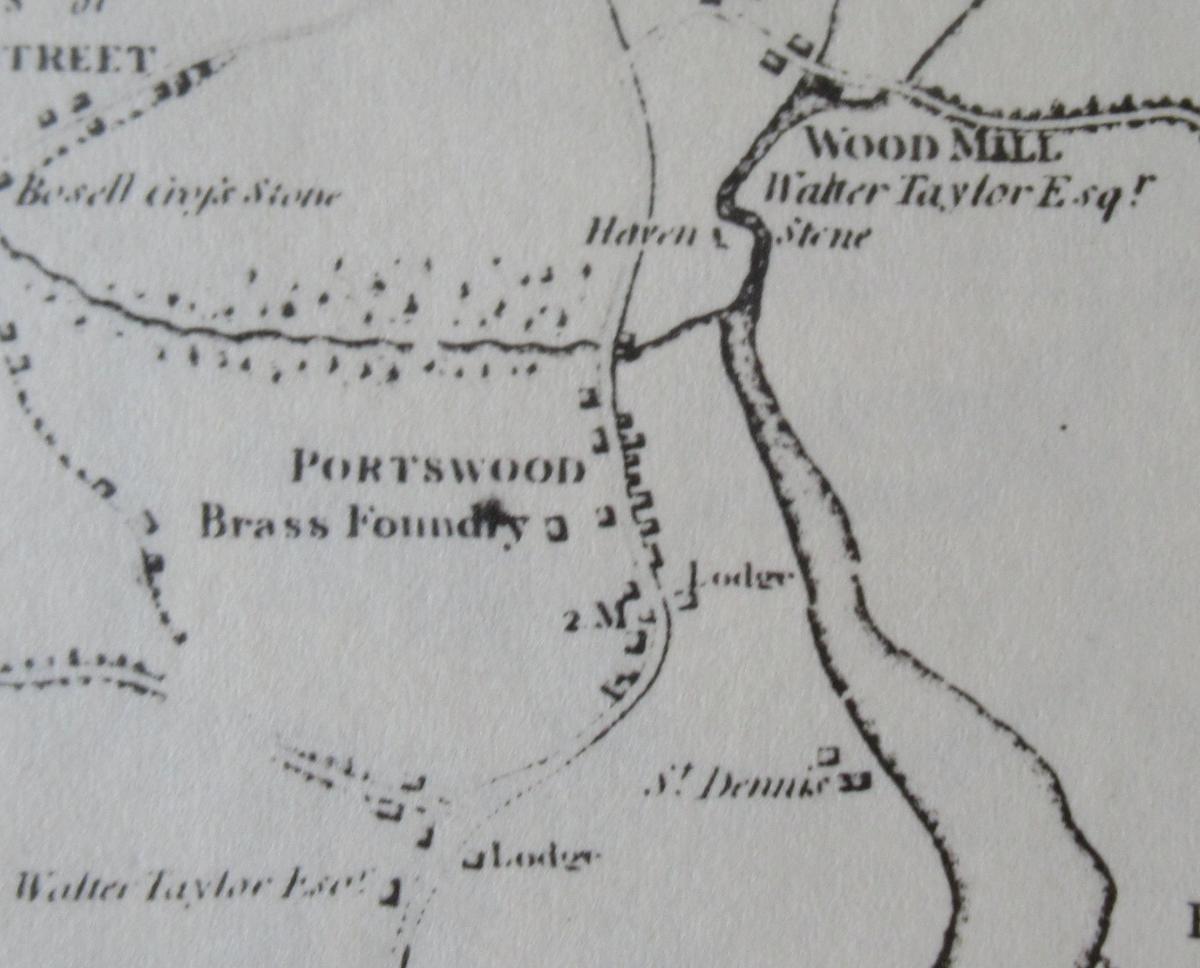

The business had expanded into parts of Bugle Street and a little later moved to Mayfield Park in Southampton where a stream provided the power for the machinery.

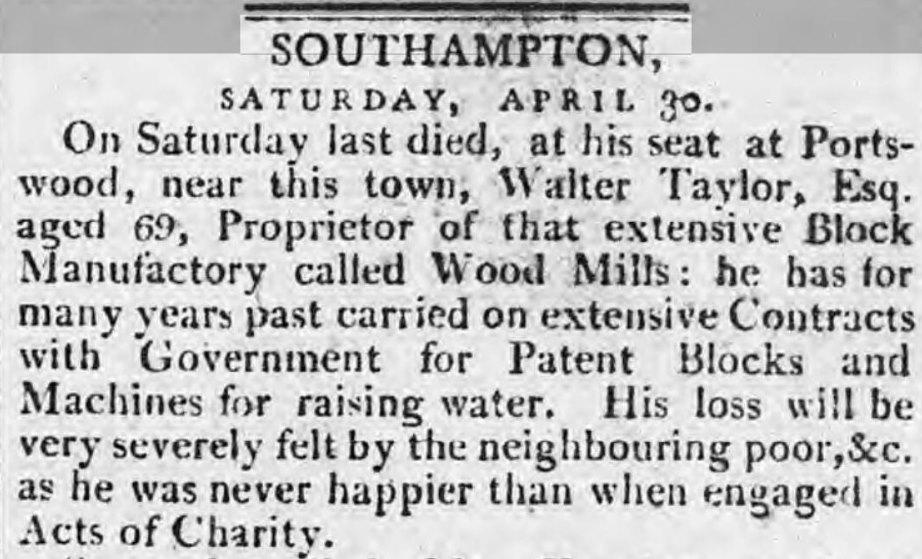

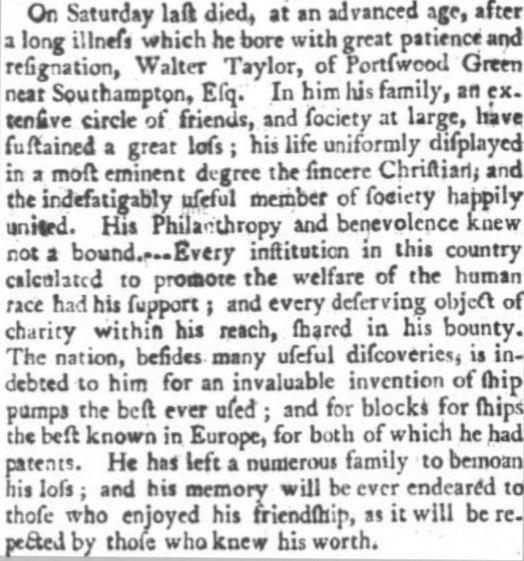

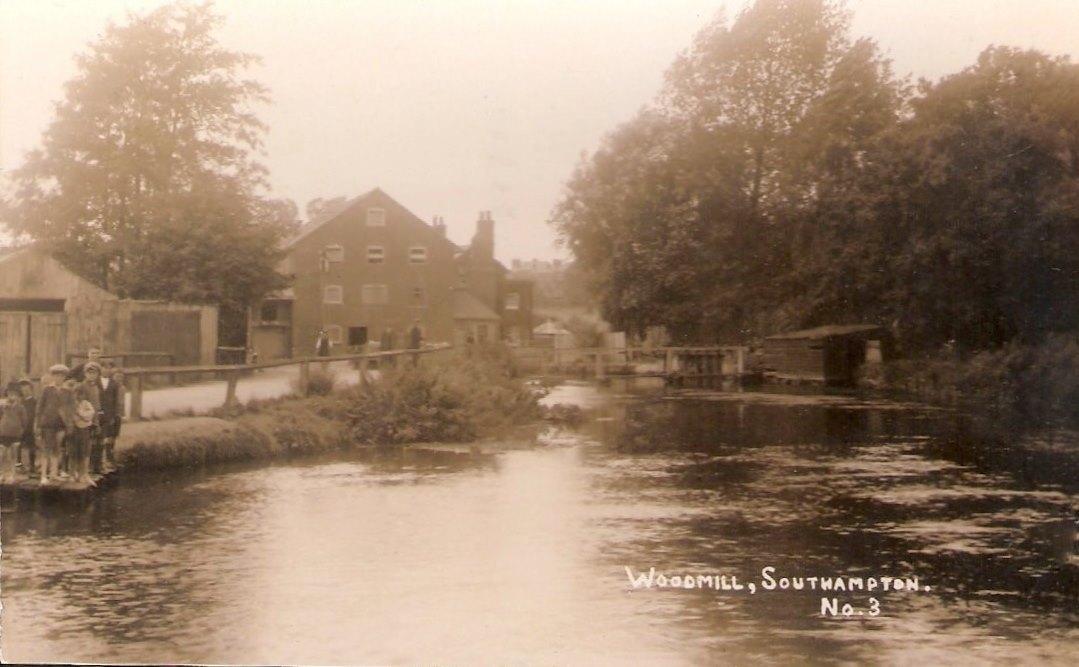

Walter was now producing 100,000 blocks a year for the navy and in 1781 the business moved to Woodmill where the river provided more power and was supplemented by steam engines. Ever the innovator, Walter also produced ship pumps which were the first with the head lowered into the ship’s bilge and is credited with inventing the circular saw.

Walter lived in Portswood on the site of the library on the Broadway and was a philanthropic employer setting up a school for his employees’ children. In Southampton Art Gallery is a painting of a new year’s feast he provided for them.

In 1801 the admiralty were in discussion with Walter regarding new block-making machinery designed by Marc Brunel, the father of Isambard Kingdom Brunel which eventually meant manufacturing of the blocks was moved in-house to Portsmouth Dockyard in 1803.

At Trafalgar the rigging and cannons of Nelson’s fleet were fitted with pulley blocks manufactured in Southampton by Walter Taylor, while the enemy still used unreliable handmade blocks. The efficiency and reliability of Walter’s blocks together with the skill of the British sailors meant that Nelson’s ships had far greater speed of manoeuvrability but, most importantly, each British cannon could fire as many as four volleys to the enemy’s one at the same time.

The Taylor’s enterprise and ingenuity played its part in Nelson’s great victory at Trafalgar.

Walter died on April 23, 1803 and was buried at South Stoneham church.

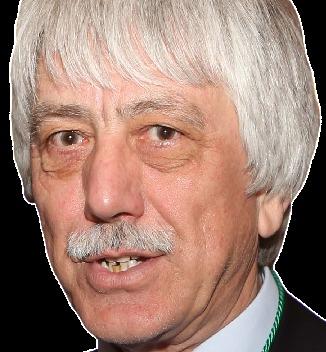

This article is written by Godfrey Collyer, who is a tour guide with SeeSouthampton.co.uk

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel